How an automatic transmission works

Overview of the various parts of automatic transmissions and their functions

Published: 2018-01-20 05:30:00

Last edited: 2025-05-19 08:37:43

Author: Administrator

What is an automatic transmission and how does it work?

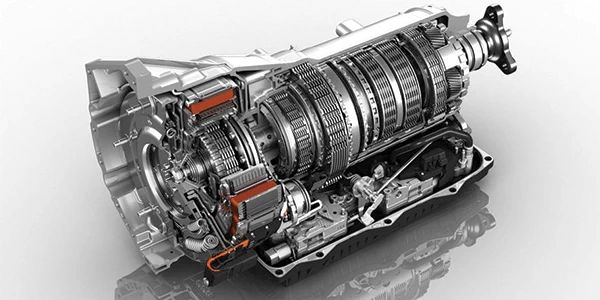

Today's automatic transmission is one of the most complex and interesting parts in cars, and to explain this advanced technology, we need to divide it into four parts.

1- Mechanical 2- Hydraulic 3- Electrical 4- Computer

These four parts in an automatic transmission work in special coordination with each other, making the transmission work and driving more comfortable and enjoyable. Until one of these parts has a problem that causes it to not work properly, that's when you notice the faults and problems in your transmission or car. The turbine in automatic transmissions and the clutch in manual transmissions both do the same job, but they are completely different in terms of how they work, and it must be said that the operation and technology of the automatic transmission are very complex.

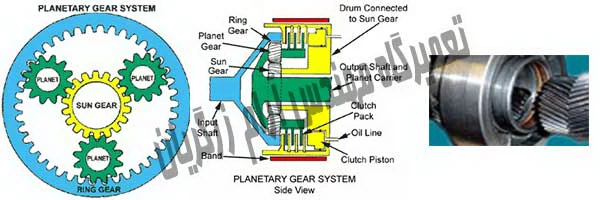

To explain the type of operation of an automatic transmission, first imagine what a car would be like without a transmission. Without a transmission, power and speed are completely limited. For example, imagine driving a gear car only in third gear. You may not have driven like this before. But if you drive like this, you will definitely see the car slow down during the initial movement and you will also find that at speeds above 100 km or 120 km, the car engine makes a lot of noise and the engine tachometer reaches the red zone and no longer goes fast and smooth. So we found that by changing the gear ratio, the gearbox changes the torque and engine speed as necessary and provides the car with the engine to work at a suitable and useful distance. One of the main differences in an automatic gearbox with a gear gearbox is that a gear gearbox engages and disengages by locking the gears that are freely mounted on the output shaft on the bearing or by means of a slider and a lever, or in low models, by moving the gear shaft, they overlap or disengage, and in this way the gears engage or disengage and cause the ratio in the gears to change. But in an automatic transmission, all gears are always engaged, and by holding one gear and moving another, a type of gear ratio is achieved. This type of gear system is called planetary or sun gears due to its similarity to the sun and planets.

Sun gears:

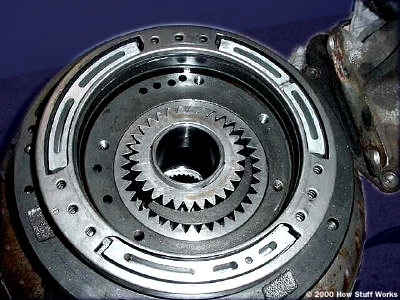

The simplest type of sun gear, consisting of a sun gear, two or more planet gears, and a ring gear. These gears are constantly engaged, and the planet gears are all connected by a shell and rotate freely around their axis in this shell. For example, in terms of use and structure, the operation of this system is as follows: by connecting the spur gear to the input shaft, which is responsible for transmitting power from the engine, and by connecting the planetary gears to the output shaft, and by keeping the sun gear fixed, if we rotate the spur gear in this case, the planetary gears will rotate around the spur gears (in this case, the sun gear is fixed), causing the input shaft to rotate in the same direction as the output shaft, with the difference that the output shaft is less than the input, which in this case is the heavy gear or (gear one), or if we release the sun gear to rotate and connect any of the other gears, in this case both the input and output shafts will rotate in the same direction and their speeds will be the same, like the four-speed gear of cars with conventional gearboxes. Another type of operation of the sun gears is that by keeping the planetary gears fixed and transmitting power to the belt gear, the sun gear will move in the opposite direction to the belt gear, or reverse gear.

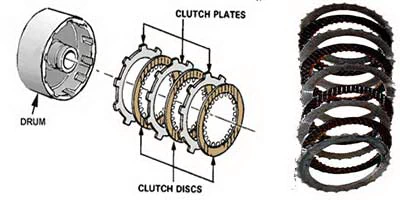

Clutches: Multi-plate clutches

Clutches: Multi-plate clutches This type of clutch consists of several clutch plates located inside a clutch bowl. Half of these plates are made of iron with teeth on their outer surface that engage the inside of the bowl, and the other half are fiber plates that have teeth on their inner surface that engage the shaft. A piston is located inside the clutch plate that is operated by the pressure of the oil plate, and when needed, the oil pressure of the piston presses the plates inside the bowl together, causing the plates to be integrated, and consequently the shaft and bowl. When the oil pressure is not under the piston, the plates are released and this integration is lost, and the shaft becomes free without a clutch plate.

One-way clutches:

A one-way clutch or sprocket is a device that locks another device, such as a gear or shaft, in one direction and rotates freely in the other. For example, in the operation of a bicycle, while the pedals can move the wheel, the wheel of the bicycle cannot rotate the pedal. As a result, when riding a bicycle, you can stop pedaling whenever you want, or hold the pedal while pedaling, or pedal in reverse without disrupting the movement of the bicycle. In an automatic transmission, the sprocket in first gear is usually used more than the other gears. When the car starts moving from a standstill, the transmission is in first gear. If you pay attention, if you release the gas pedal in this case, the car moves forward like a free gear. Now, if you move in Low or L gear, the gear is the same at the beginning of the movement, but if you take your foot off the gas pedal, you will feel the engine brake like a car with a regular gearbox. This action is one of the distinctive features of the sprocket, which in automatic transmissions makes driving smoother. By adding a band or clutch, you can remove the sprocket and use the engine when necessary.

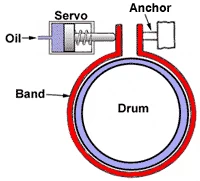

Brace Band:

The band is a metal strap to which brake pads are attached from the inside. One end of it is connected to the shell and the other end to the piston by a lever. Whenever oil enters the cylinder, it pushes the piston back and the lever causes the band to tighten and adhere to the surface of the bowl, thus braking the bowl and stopping the bowl.

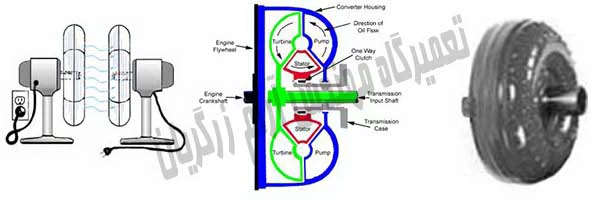

Oil clutch or turbine:

In automatic transmissions, the oil clutch or turbine performs the function of a clutch in cars with a conventional gearbox. The turbine allows the car to start when the engine is stationary and stops, and as soon as the brake pedal is released and the gas pedal is pressed, it transfers the engine power to the input shaft and, consequently, to the output shaft. The principle of operation of this turbine is that if we place two electric fans opposite each other and then connect one to the power supply to rotate, the second fan, which is not powered by electricity, will also rotate due to the air flow. If you grab the second fan blade, you can hold it, and as soon as you release it, it will rotate again and start accelerating until the speed of the second fan reaches the speed of the first fan. This type of operation is the principle of operation of oil clutches or turbines, but in the turbine, oil is used instead of air. The turbine is a large piece with a diameter of 25 to 50 centimeters, in the shape of a short pot or cylinder, located in front of the gearbox between the engine and the gearbox. It is connected to the engine crankshaft via a flywheel and is responsible for transmitting engine power to the gearbox input shaft.

Hydraulics:

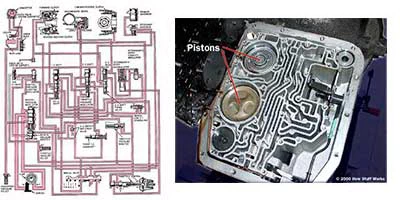

The transmission hydraulic system consists of many complex grooves that deliver oil under high pressure to other parts of the transmission and turbine. The diagram on the left is of a simple three-speed transmission that was produced in the 1960s, and this diagram is one of the simplest types of automatic transmissions. Today's models are much more complex and have added computer systems and electronic components. Transmission oil performs several functions in an automatic transmission.

1- Oil pressure to control the gears and clutches of the transmission.

2- It is used to lubricate the overall transmission parts and finally to cool the transmission. In an automatic transmission, all functions depend on oil and proper and continuous oil pressure.

Automatic transmission pump:

The pump is responsible for producing the oil pressure required by the gearbox. The transmission pump is located at the front of the gearbox and is directly connected to the turbine throat, and the turbine itself is connected to the engine crankshaft by the flywheel. As a result, when the engine starts, the transmission pump also starts moving and produces the oil pressure required by the gearbox.

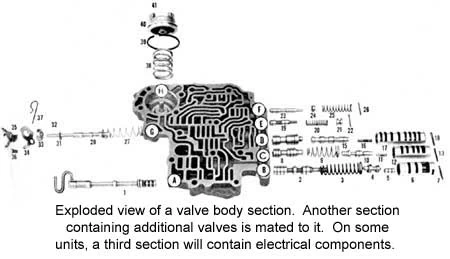

Control valve or (gearbox clock):

This part controls all the functions of the gearbox using oil and can be simply said to be the brain of the gearbox. This part consists of a shell on which all the oil channels and inside the shell are the control valve valves. The valves, by moving (against springs or oil pressure) and changing their position, regulate the oil pressure, send oil to the clutches, servos, turbine and gear changes at the right time and with the right quality and cause the gearbox to function. Each gearbox valve has its own specific task and is named with that task, for example, the two-to-three valve that is responsible for changing gears from two to three or the three-to-two valve that is responsible for reversing gears from three to two. Control valves of cars older than 1995, solenoid valves and speedometers (speed sensor) were also added to it. The image shows a simple type of gearbox control valve (TH350) manufactured in 1975.

Electronic system:

The computer (ECU) uses sensors in various parts of the car, engine, gearbox, ABS, etc., to collect the information it needs, such as the position of the gas pedal (the position of the air intake valve to the engine), car speed, engine speed, engine load (negative torque), the position of the brake button under the pedal, etc., to enable gear changes at a specific and precise time, and even soft and rough (clutch engagement with high oil pressure and rapid clutch engagement and gear changes). Some models of modern and electronic automatic transmissions can even learn and memorize your driving style and change gears exactly as you like.

In terms of the type of computer structure and the range of operations it can perform, today there are cars with automatic transmissions with a sports model (tiptronic) on the market that allow you to control gear changes that work like cars with a conventional gearbox, that is, they operate both automatically and in a conventional gear. These tasks are mainly done by moving the gear lever from inside the groove provided for the gear lever. It is built-in and allows you to increase or decrease the gears by moving the gear lever up and down. Another advantage of the computer is that it constantly diagnoses itself and notifies the driver if there are any faults or problems in the electrical parts or even the gearbox itself by giving an alarm or turning on a light inside the speedometer. If this alarm or light occurs, the car should be taken to a repair shop and by connecting a scanner or test device, the list of faults stored in the computer's memory can be read and the fault can be identified by a test drive by a gearbox specialist.